Leading the Future of Energy Storage Solutions.

Quality Materials, Innovative Technology

backed by the best in class energy management.

In-house designed and manufactured solutions ensuring quality at every step.

Power at any scale - Homes, businesses, industries, utility scale applications.

Energy systems designed for on-grid or off-grid applications.

Maximise performance & lifespan with our best in class Intelligent management software.

Residential Solutions.

High-quality lithium iron phosphate batteries for your home.

Our scalable home energy storage solutions range from the SS4083 (8.3 kWh) for smaller homes, SS4160 (16 kWh) for a bit extra power, to the SS216 (16 kWh – 512kWh) for maximum energy independence, allowing you to start with what you need today and expand as your demands grow with the assurance of modular design, customisable capacity, future-proof adaptability, and reliable performance.

The ultimate home energy solution. Unleash modular power from 16kWh to a massive 512kWh.

Explore all our Solutions.

Sustainable Energy

Scalable solutions for residential, commercial, industrial and utility scale operations.

Powering the Home

Residential

Our home energy storage solutions fit your needs—whether for backup power, lower bills, or off-grid living. All systems are modular and expandable to grow with your energy demands.

Products- NEW SS216

- NEW SS4160

- SS4083

Powering the Business

Commercial

Quality energy storage that grows with your business. Explore our Low and High Voltage solutions designed for maximum performance and scalability.

Products- Low Voltage – SS216 (16 – 512kWh)

- High Voltage – SS70xx (16 – 272 kWh)

Powering the Nation

Industrial & Utility

High Voltage battery systems that combine an advanced energy management system with robust design, maximizing performance and efficiency even in the harshest conditions.

Products- SS70xx Cabinet Range (16 – 272 kWh)

- Containerised BESS (500 kWh – 6.5 MWh)

Our Products.

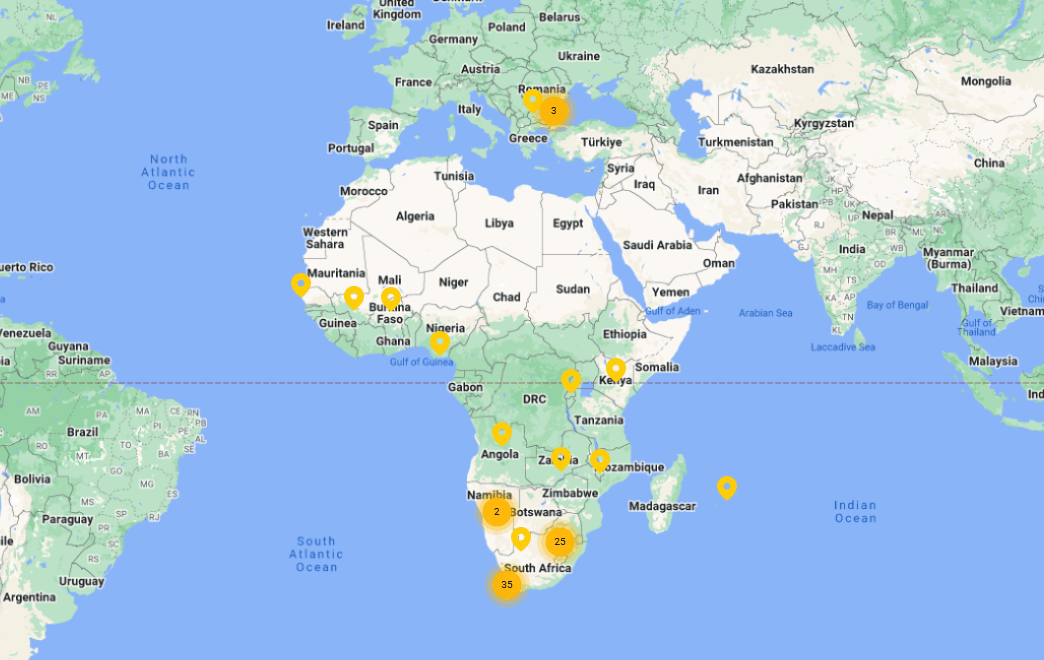

Our Presence.

Global reach with solutions deployed worldwide.

Since 2014, Solar MD has been a pioneer in sustainable energy storage, empowering homes, businesses, industries and utilities worldwide with reliable and affordable clean energy solutions. Today, with hundreds of thousands of units across 50+ countries, we continue to lead the future of energy storage. Our cutting-edge solar and battery technology is not just about powering the world; it’s about building a brighter, greener future for everyone. Join us on this journey towards a sustainable tomorrow.

Trusted Clients.

Case Studies.

Increase Self-Consumption

JAEGGI has a long and successful tradition in equipment and instrument manufacture. It was founded in 1929 in Berne (Switzerland) as a company of coppersmiths and tin platers.

Increase Self-Consumption

Therme Bucuresti, located in the northern area of Bucharest, in Balotesti and belongs to A-HEAT GROUP, a concern based in Vienna, which brings together several leading companies worldwide …

Battery Backup for critical Pump Infrastructure

Lebalelo is a water user association, comprising of both thecommercial mining sector and the South African Department of Water and Sanitation.

Inverter Compatibility & Support.

Versatile Compatibility

Approved Channel

Partners.

Find Your Distributor, Installer and Wholesaler

Solar MD has partnered with reputable distributors for ease of access to our Energy Storage products throughout Africa and Europe. Each of our Solar MD approved installers have a strong track record and are constantly reviewed for quality control and product installation optimisation with direct access to …